Variable rate seed prescriptions have been a topic of conversation since planter capabilities have increased and seed companies look to increase the value of their recommendations. Yet the farmgate, conversations have had a range of reactions to its success.

“I tried it but variable rate prescriptions do not work on my soils.”

“It didn’t pay in corn but I am using variable rate on my soybean acres.”

“I run prescriptions across every acre of the operation and it’s made a difference.”

“The hybrids change so often; variable rate seeding takes too long to get correct.”

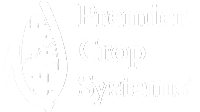

These responses lead me to ask, “What measure of success is being used?” I feel the measure of success cannot be seed cost savings or overall yield increase alone. The measure of success needs to be improved profitability at a subfield level. At Premier Crop Systems (PCS) we call this Yield Efficiency.

In the image below you can see the gauge on the top shows an anonymous grower group where the grower has the highest yield in the group of 222.6 bu/ac (yield gauge on the top ranges from 169.2/bu - 222.6/bu). The gauge on the bottom shows a range of yield efficiency, return to land and management, of $240.98 - $555.23 at a benchmark selling price of $3.75/bu. The grower is leaving money on the table as his yield efficiency is only $474.08 even though he had the highest yield in the group, equating to a lost profit potential of $81.15 per acre.

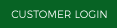

So how do we build a comprehensive plan that includes Variable Rate Seed Prescriptions, to measure profitability at a subfield level? This process starts with building production zones across the field. These zones should be custom built with an advisor using the grower’s expectations/goals and production history of this field. This provides the opportunity for the grower to pick areas of the field that they feel can be pushed to a higher production level and those areas that should realistically be lowered.

Once the production zones are established, a comprehensive plan is built tying fertility and seeding rates together with grower’s goals. There has to be the right amount of nutrients for the number of plants or guests invited to the table. For example, you can’t feed 30 people on 8 pizzas but you’ll waste pizza if you only have 10 people. In order to properly feed the guests/plants, you need to fertilize to your soil test level and build goals as well as using the actual yield removal rates across that same subfield location. Following up with a variable rate nitrogen program built to support the yield goals/expectations in those subfield locations. Tying all of the variable rates with costs, along with the actual yield and selling price at a subfield level in PCS can get a grower to a true ROI on variable rate seeding.

Wait, backup. How do we evaluate what rates to plant a hybrid within our zones when hybrid longevity can be so short? Most seed companies have suggested seeding rate ranges based on their research across different productive soils. But that doesn’t necessarily line up with the grower’s farms. That is why the Enhanced Learning Blocks (ELB) from PCS turns a grower’s field into its own research farm. These Enhanced Learning Blocks are university style replicated and randomized trials custom placed in the built production zones. A grower can use ELB’s to evaluate the right rates on their fields for new hybrids faster. Therefore, helping the grower find the most profitable rate and location years before a good hybrid is retired.

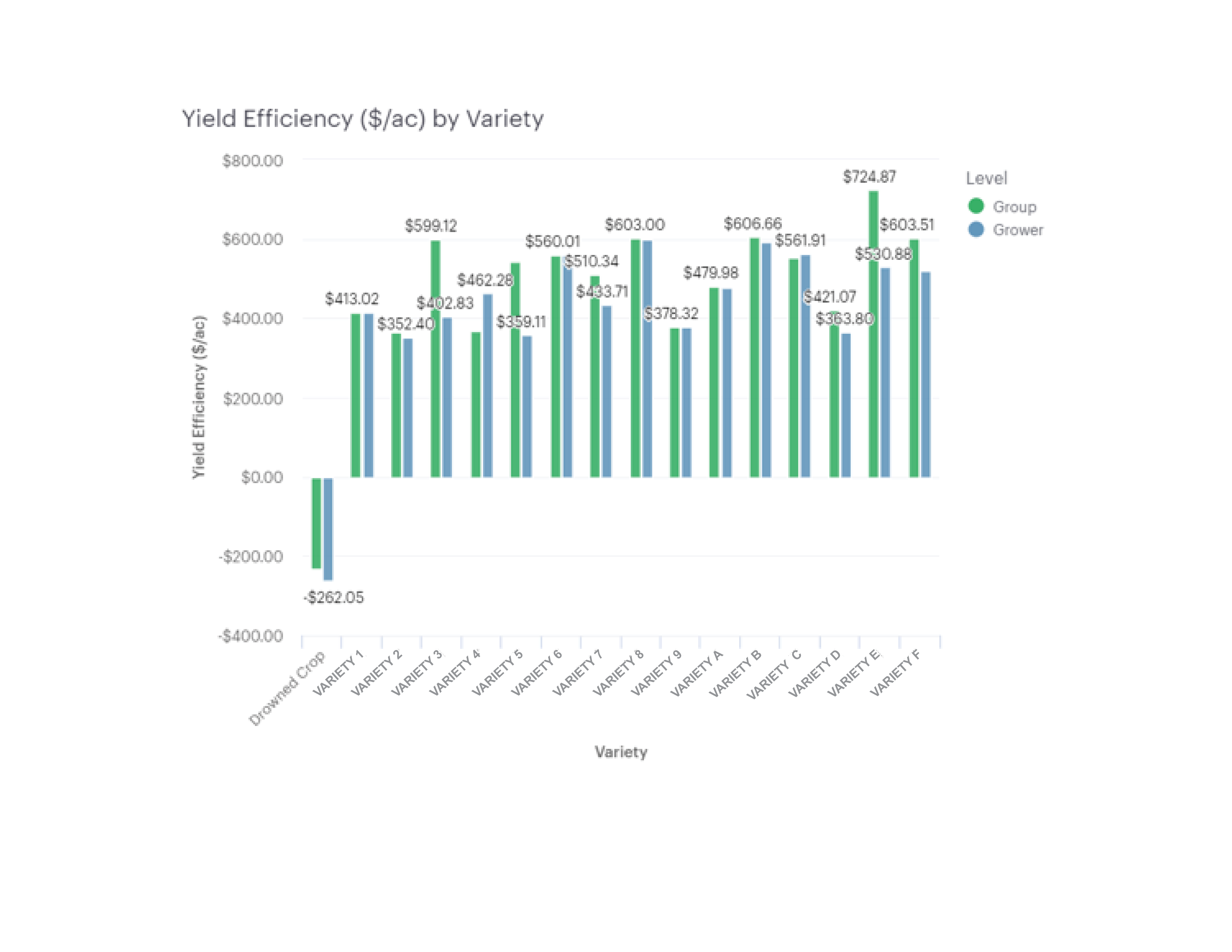

Beyond the growers field the benefits to being involved in our system is all of the anonymous grower data that can tell you which hybrid or variety has the highest yield efficiency in your area. There are so many choices, how do you know you are profiting from your decisions?

Do I need to do all of these steps if I am just starting out? The short answer is no. The most important first step is building out your production zones. From there, start tying in the different variable rate practices to those zones. All of the elements of the comprehensive plan discussed, needs to be the goal to work towards.